LDM, LA DIMENSION MÉCANIQUE,

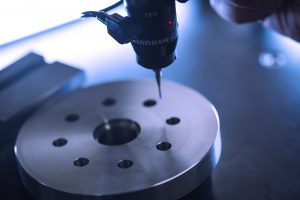

TECHNOLOGICAL PERFECTION THROUGH HIGH-PRECISION MECHANICS

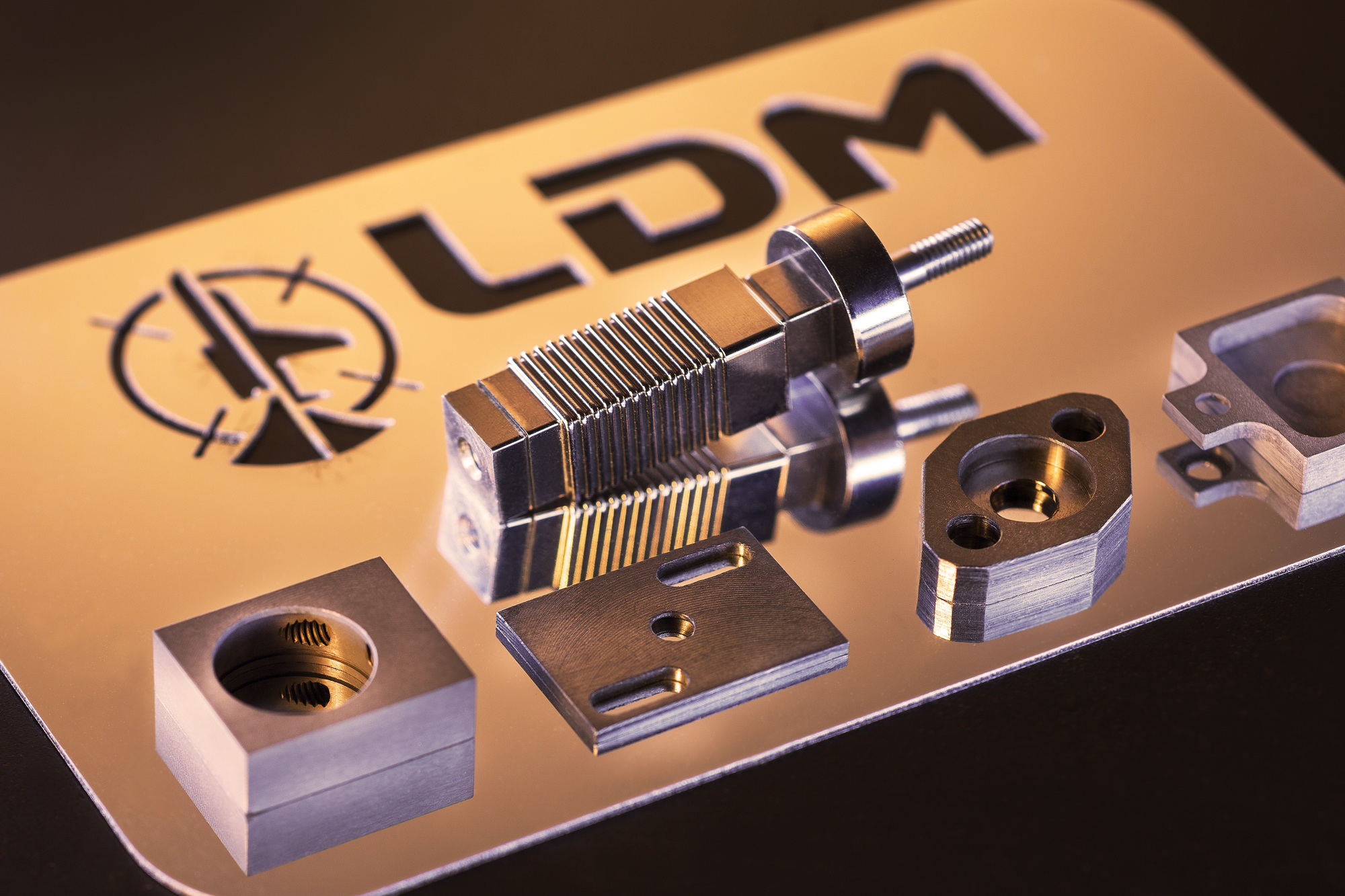

LDM HAS BEEN DESIGNING AND MANUFACTURING ALL TYPES OF MECHANICAL PARTS FOR ALMOST 50 YEARS, WITH A KNOW-HOW AND QUALITY THAT HAVE MADE IT ONE OF THE LEADING PLAYERS IN HIGH-PRECISION MECHANICS.

Equipped with leading-edge design and production systems, our engineers use the most innovative computerised tools for programming and industrial production to meet even the most stringent demands in the aeronautical, aerospace, energy, transport, automotive, sports (rallies, Formula 1, etc.) and medical sectors.

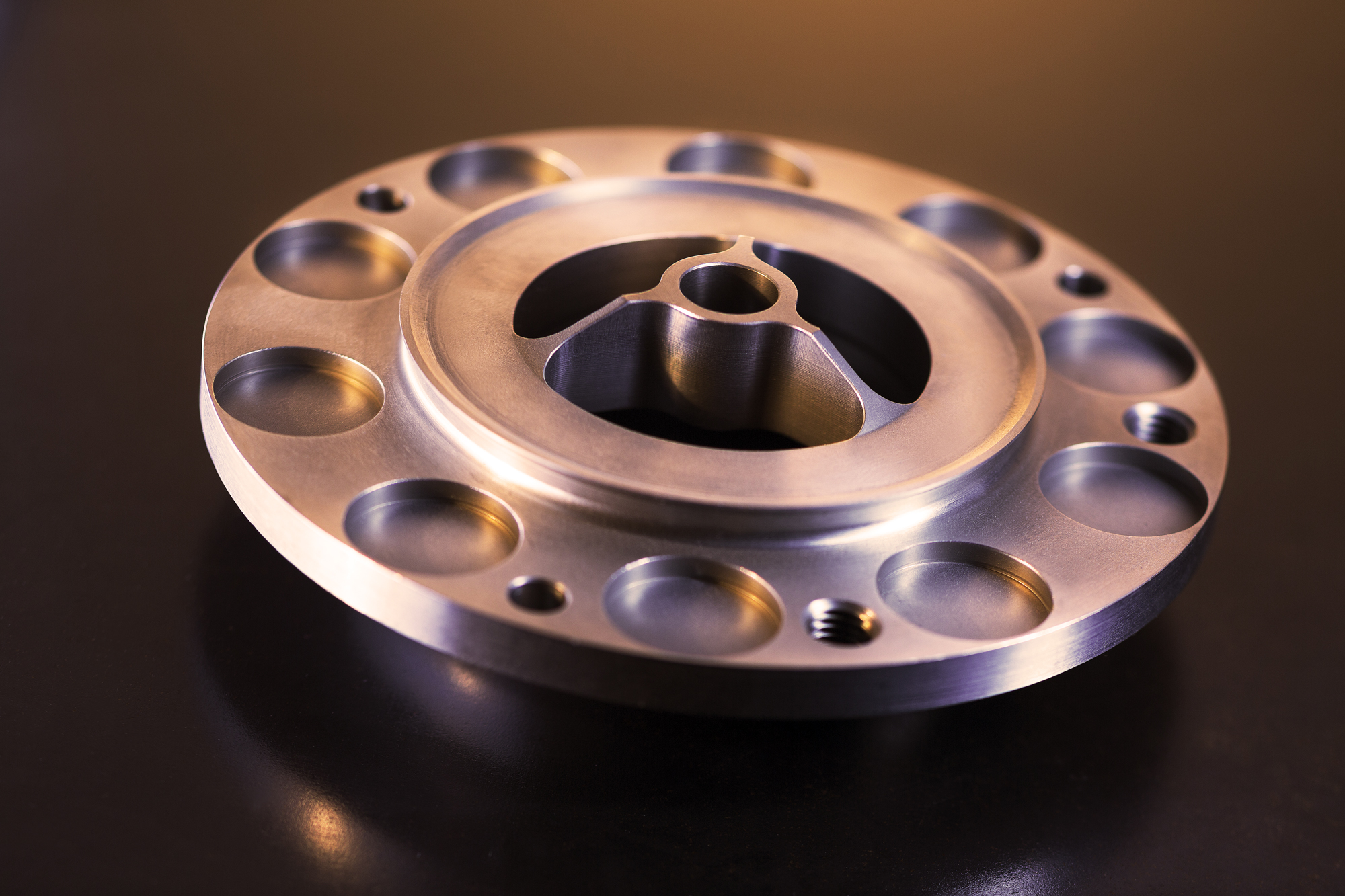

We meet our customers’ demands for quality and precision by machining both the most common and the most exotic materials (titanium, stainless steel, aluminium, Invar, Kovar, copper, tungsten, bronze, brass, composites, etc.), and we can manufacture your products from end to end, from the sourcing of materials and castings, to the delivery of the treated parts.

KNOW-HOW

LDM IS INTERNATIONALLY RENOWNED FOR THE PRECISION AND THE QUALITY OF BUILD OF ITS MECHANICAL PARTS.

Positioned as a specialist in the production of critical or vital parts with tolerances of a few microns, our engineers use the very latest computerised programming and industrial production software (CATIA, Mastercam, Missler) and invest 30% of their resources into the research and development of new machining processes for precision parts.

We operate in numerous fields and pay very close attention to the advice we offer our customers, to the quality of our products and to the working environment and conditions of our engineers.

We manufacture very high-precision small parts (micromechanics), starting at 1 mm3, and medium-sized parts measuring up to 800 mm3 for a varied range of machining operations: NC LATHING - NC GRINDING - STRAIGHTENING - HONING - ELECTRO-EROSION - MICROMECHANICS - HIGH-PRECISION TURNING

The quality of our EN/AS/JISQ 9100 and ISO 9001-certified machining, precision, inspection and production of parts reflects our know-how and our application of procedures.

The guarantee of the ever-increasing quality of these products has enabled us to implement the most demanding leading-edge programmes and to contribute to the progress of the most advanced techniques, in order to offer a better response to our customers’ needs.

We achieve this by permanently applying our quality policy, meeting the international standards in force (manuals, procedures, internal audits, product audits) and keeping track of every internal and supplier-sourced product.

REFERENCES

PRECISION AND HIGH STANDARDS WORKING FOR THE GREAT INDUSTRIAL INNOVATIONS

Because our customers are our best references, because they trust us to produce mechanical parts to faultless standards of high precision and quality, and because we are proud to work with the leading players in aviation, aerospace, energy, transport, etc.

DO YOU WANT TO JOIN US?

Looking for an internship, a permanent or temporary contract, a work experience placement? We are always on the lookout for new talent.

Check out our job offers or apply directly to jobs@ldmeca.com

CONTACTS

ZAC DES CHEVRIES - 15, RUE DES CHEVRIES

78410 AUBERGENVILLE - FRANCE

TÉLÉPHONE : +33 (0)1 30 04 15 00

FAX : +33 (0)1 30 04 15 01

ACCESS BY RAIL ON LINE N - CLOSE TO THE A13 MOTORWAY

contact us by e-mail: info@ldmeca.com